Perché ogni team di manutenzione dovrebbe monitorare l'usura e l'allungamento delle catene industriali

L'usura delle catene industriali è prevedibile e misurabile.

Per i team di manutenzione, il monitoraggio degli indicatori di usura corretti è la chiave per prevenire guasti improvvisi, migliorare la sicurezza e prolungamento della durata della catena.

Perché le catene industriali sono componenti soggetti ad usura, affidarsi solo all'esperienza o ai controlli visivi non è sufficiente. Una volta che si manifestano rumori anomali o guasti, l'usura ha già raggiunto uno stadio critico. Per passare da riparazioni reattive A manutenzione predittiva, i team devono monitorare sistematicamente un piccolo insieme di indicatori misurabili.

Le tre metriche seguenti rappresentano gli indicatori più importanti dell'usura delle catene industriali che ogni team di manutenzione dovrebbe monitorare.

Tasso di allungamento della catena

Allungamento della catena è causato principalmente da indossare tra perni e boccole, che porta a un aumento permanente della lunghezza complessiva della catena. Questo è uno degli indicatori più affidabili dell'usura della catena e della sua durata residua.

Come misurare l'allungamento della catena

L'allungamento deve essere misurato su almeno 8 passi di catena consecutivi. Confrontare la lunghezza effettiva misurata con la lunghezza nominale (standard) e calcolare la percentuale di allungamento:

Allungamento (%) = (Lunghezza misurata – Lunghezza standard) / Lunghezza standard × 100

La misurazione su più passi migliora la precisione e riduce al minimo gli errori di misurazione locali.

Come interpretare i limiti di allungamento

I limiti di allungamento accettabili variano a seconda dell'applicazione e del settore. Tuttavia, per sistemi di trasmissione a catena industriali generali, le seguenti linee guida sono ampiamente utilizzate:

- Allungamento ≥ 1,5% Aumentare la frequenza delle ispezioni e preparare i pezzi di ricambio.

- Allungamento tra 2% e 3% (o prima se richiesto dall'applicazione) Si consiglia la sostituzione immediata per evitare danni alla ruota dentata e salto della catena.

- Sistemi di trasmissione di precisione Potrebbero essere applicati limiti più severi, con sostituzione richiesta a Allungamento 1% o meno.

Il monitoraggio dell'allungamento consente ai team di manutenzione di intervenire prima che si verifichino danni secondari, in particolare per pignoni e alberi.

Tensione di installazione della catena

Tensione di installazione della catena è strettamente correlato all'allungamento della catena e all'usura complessiva del sistema. Un catena troppo tesa aumenta il carico aggiuntivo sulla catena, sulle ruote dentate e sui cuscinetti, accelerando l'usura e aumentando il rischio di guasti.

È essenziale controllare regolarmente il gioco della catena durante il funzionamento.

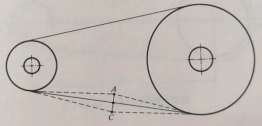

Come valutare la corretta tensione della catena

I requisiti di tensione della catena dipendono dagli standard applicativi e dalla configurazione del sistema. Per l'uso industriale generale, si fa comunemente riferimento alle seguenti linee guida:

- Quando la linea tra i centri dei pignoni è inferiore a 45° rispetto all'orizzontale Il movimento verticale tra le posizioni A e C dovrebbe essere Da 2% (±1%) a 6% (±3%) della distanza centrale.

- Quando l'angolo supera i 45° rispetto all'orizzontale Il movimento consentito dovrebbe essere Da 1% (±0,5%) a 3% (±1,5%) della distanza centrale.

- Quando i pignoni sono allineati verticalmente (90°) Il gioco della catena deve essere ridotto al minimo possibile, garantendo al contempo un innesto e un funzionamento fluidi.

Un controllo adeguato della tensione aiuta a mantenere un accoppiamento stabile, riduce le vibrazioni e limita l'usura aggiuntiva causata da carichi eccessivi.

Condizioni di lubrificazione e contaminazione

La lubrificazione gioca un ruolo decisivo nel controllo dell'usura della catena. Una lubrificazione insufficiente o un lubrificante contaminato agiscono come acceleratori di usura, riducendo significativamente la durata della catena.

In molti casi, la semplice pulizia della catena e l'applicazione del lubrificante corretto sono la soluzione misura di controllo dell'usura più efficace.

Come ispezionare le condizioni di lubrificazione

I team di manutenzione devono ispezionare visivamente la superficie della catena e valutare:

- Se la catena appare asciutto o adeguatamente lubrificato

- Che sia un sottile pellicola d'olio è presente

- Se la catena è coperta da grasso sporco, abrasivo o contaminato

L'utilizzo del tipo corretto di lubrificante e il mantenimento della pulizia aiutano a prevenire l'attrito a secco, riducono l'usura nelle interfacce perno-boccola e stabilizzano le prestazioni della catena.

Indicatori di usura chiave a colpo d'occhio

| Indicatore di usura | Cosa controllare | Rischio se ignorato |

| Tasso di allungamento della catena | Aumento permanente della lunghezza | Salto della catena, danni alla ruota dentata |

| Tensione di installazione | Eccessiva rigidità o allentamento | Usura accelerata, vibrazioni |

| Condizioni di lubrificazione | Presenza e pulizia dell'olio | Usura rapida, attrito secco |

Conclusione

Tracciando sistematicamente allungamento della catena, tensione di installazione e condizioni di lubrificazione, i team di manutenzione possono prevenire guasti improvvisi causati da attrito a secco o usura eccessiva. Ancora più importante, questi indicatori consentono ai team di prevedere la durata dei componenti, ottimizzare l'inventario dei pezzi di ricambio e pianificare le attività di manutenzione in modo più efficace.

Il risultato è una transizione dalle riparazioni di emergenza a manutenzione predittiva basata sui dati, offrendo entrambi riduzione dei costi e funzionamento più sicuro e affidabile.