Migliori pratiche di lubrificazione per catene a lamelle in carrelli elevatori e attrezzature di sollevamento

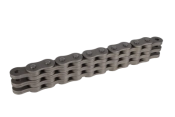

Catene di foglie svolgono un ruolo fondamentale nei carrelli elevatori, negli elevatori a forche e in altre attrezzature di sollevamento. In quanto componenti chiave per la trasmissione del carico e del movimento, le loro condizioni di lubrificazione influiscono direttamente affidabilità operativa, efficienza di sollevamento e durata complessiva del servizio. Una lubrificazione insufficiente è una delle cause più comuni dell'usura prematura della catena e dei tempi di fermo imprevisti.

Per garantire prestazioni stabili anche in presenza di carichi pesanti, la corretta gestione della lubrificazione deve essere considerata una parte fondamentale della manutenzione ordinaria.

Selezione del lubrificante giusto

Le catene a foglia utilizzate nelle applicazioni di sollevamento operano sotto carichi statici e dinamici elevati, spesso combinati con forze d'urto. Per questo motivo, gli oli leggeri standard non sono sufficienti.

Si consiglia di utilizzare oli o grassi per catene ad alta viscosità con forte adesione e proprietà di estrema pressione (EP), come i lubrificanti contenenti bisolfuro di molibdeno (MoS₂). Questi lubrificanti possono penetrare nelle aree di contatto interne e mantenere una pellicola di olio protettiva anche sotto carichi pesanti e cicli di sollevamento ripetuti.

Catene Universal Catene a lamelle serie BL sono progettati con tolleranze ottimizzate per perni e piastre, consentendo ai lubrificanti di penetrare efficacemente nelle aree soggette a usura e di fornire una protezione a lungo termine nelle applicazioni di sollevamento più impegnative.

Lubrificazione dei punti critici di usura

Le zone di lubrificazione più importanti in una catena a lamelle sono le aree di gioco tra perni e piastre di collegamento (o fori delle piastre). Queste interfacce sono sottoposte alla massima pressione di contatto durante le operazioni di sollevamento e sono la principale fonte di usura.

La lubrificazione deve essere applicata utilizzando un pistola per olio a pressione manuale o sistema di lubrificazione centralizzato per garantire che il lubrificante raggiunga le superfici di contatto interne. Prima di procedere alla lubrificazione, è necessario rimuovere grasso vecchio, polvere e contaminanti abrasivi per prevenire un'usura accelerata.

Universal Chain supporta i clienti non solo con catene a foglia di alta qualità, ma anche con guida all'applicazione e raccomandazioni per la manutenzione, aiutando i team di manutenzione a lubrificare le catene in modo corretto e costante.

Controllo della frequenza e della quantità di lubrificazione

Gli intervalli di lubrificazione devono essere regolati in base a frequenza operativa, intensità del carico, condizioni ambientali e perdita visibile di olio sulla superficie della catena. Non esiste un programma fisso adatto a tutte le applicazioni.

Come regola generale, il volume di lubrificazione dovrebbe essere sufficiente a formare un pellicola d'olio uniforme sulla superficie della catena, senza gocciolamenti eccessivi o punti asciutti. Una lubrificazione eccessiva può attrarre contaminanti, mentre una lubrificazione insufficiente provoca attrito a secco e rapida usura.

La catena Universal fornisce supporto tecnico per la selezione della catena e la pianificazione della manutenzione, consentendo agli utenti di definire cicli di lubrificazione adatti alle loro specifiche attrezzature di sollevamento.

Adattamento ad ambienti operativi speciali

Le condizioni ambientali hanno un impatto diretto sulle prestazioni del lubrificante. ambienti umidi o corrosivi, si dovrebbero usare lubrificanti resistenti alla ruggine. In applicazioni ad alta temperatura, i lubrificanti con elevata stabilità termica sono essenziali per prevenire la degradazione dell'olio.

Seguendo queste buone pratiche di lubrificazione, i team di manutenzione possono ridurre significativamente l'usura, estendere durata della catena fogliare, e garantire il funzionamento sicuro e stabile delle attrezzature di sollevamento.

Conclusione

Una lubrificazione efficace non è solo una manutenzione di routine, è un strategia preventiva. In combinazione con catene a lamelle adeguatamente progettate, una lubrificazione costante contribuisce a ridurre i rischi operativi, abbassare i costi di manutenzione e migliorare i tempi di attività delle attrezzature.

Con qualità stabile, catene a foglia serie BL standardizzate e supporto tecnico reattivo, Universal Chain supporta i clienti globali nel raggiungimento di prestazioni di sollevamento affidabili ed efficienza operativa a lungo termine.