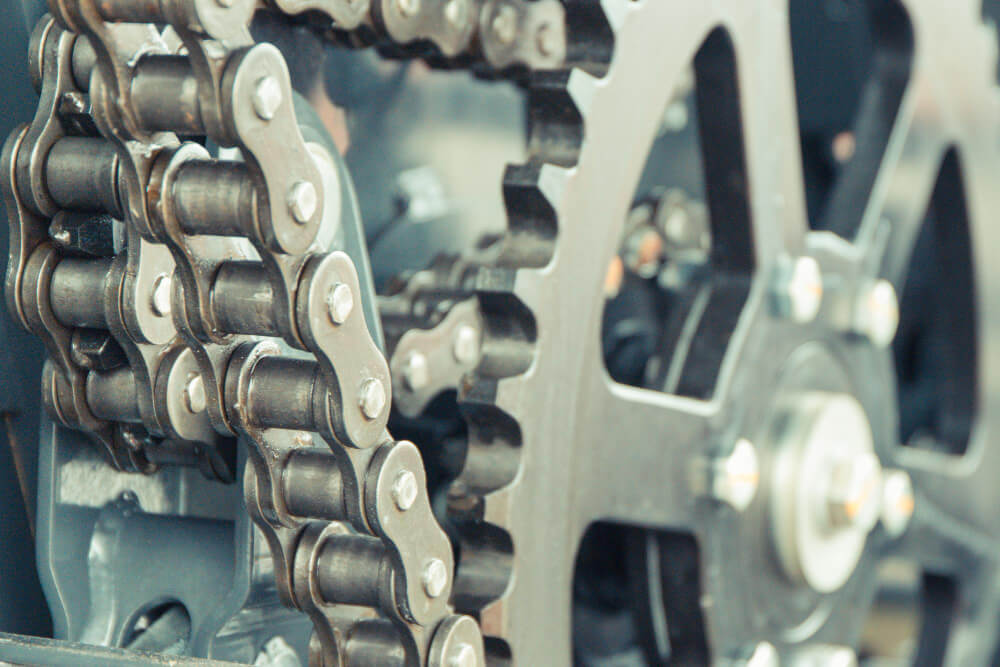

Roller chains are the backbone of power transmission. They drive countless machines across many sectors, be it industrial, agricultural, or automotive.

But how do you select the right chain for your application? To select the right roller chain, you need to know the size, material, application, and other design elements.

Following some basic guidelines will help ensure you choose a roller chain that meets your performance, lifecycle, and budget requirements.

4 Tips to Select Roller Chains

Determine The Roller Chain Size You Need

One of the first considerations is roller chain size. Roller chain sizes are designated by a numbering system based on the chain’s pitch, which is the center-to-center distance between rollers.

Common sizes include #40, #50, and #60 chains, with higher numbers indicating a larger chain with a higher load capacity. Universal Chain’s website provides detailed size charts with specifications for each chain, making it easy to find the perfect match for your application’s load requirements.

Consider Roller Chain Materials

Roller chains come in a variety of materials suited for different operating environments. The most common is basic carbon steel which provides good all-around performance for many general industrial applications.

Where corrosion resistance is required, stainless steel roller chains are an excellent choice. They withstand exposure to moisture, chemicals, and other harsh conditions.

For extremely heavy loads or high-shock applications, alloy steel roller chains offer superior tensile strength.

On the opposite end, extra lightweight roller chains made from aluminum or non-metallic materials minimize inertia and wear. Temperature extremes are another factor, with specialty chains made from heat-resistant nickel alloys available for hot environments.

Match Chain to Application

Knowing the specifics of your application will help determine the optimal roller chain type. Are tight turns or articulation required? If so, look at multi-strand leaf chains.

Does the chain need to withstand heavy shock loading? Double-pitch chains may be preferred. Is precise positioning critical? Precision roller chains provide high accuracy.

Also consider any environmental factors like moisture, chemicals, dirt, or temperature extremes that could impact chain performance and lifecycle.

Other Design Elements

In addition to chain type, several other design elements play a role in ensuring optimal performance:

- Chain Length: The chain needs to be the appropriate length for proper sprocket engagement and tensioning.

- Sprocket Selection: Sprocket size and tooth profile need to match the chosen chain precisely for smooth operation and efficient power transfer.

- Chain Tension: Maintaining proper chain tension is critical for optimal wear resistance and performance.

- Lubrication: Regular lubrication is essential for most roller chains to minimize friction and extend lifespan. Some chains come with built-in lubrication features.

- Fatigue Rating: Consider the chain’s fatigue rating, which indicates its ability to withstand repeated stress cycles without failure.

While there are many variables involved, partnering with an experienced chain manufacturer is invaluable. They can analyze your application parameters and recommend the ideal roller chain solution to meet your cost and performance targets. With their expertise guiding you, selecting the proper roller chain becomes much easier.

Contact us today to discuss your specific needs and ensure you select the perfect roller chain for your application.