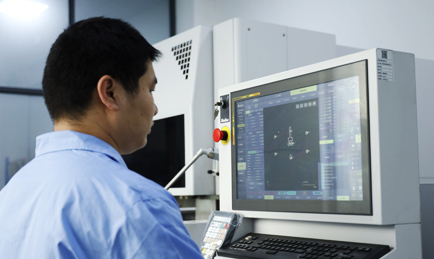

Advanced Equipment

Universal Chain has more than 2000 sets of advanced high-precision manufacturing equipment that stand in a leading station in the industry. Besides high-efficiency equipment like high-speed progressive die punching, cold heading machine, we also introduce high-efficiency and precision Slow Wire Machine, CNC, machining centers, laser cutting machines, and intelligent heat treatment multi-function furnace production lines from the developed countries in manufacturing, such as Japan and Germany. Effectively guarantee the internal quality of the products and meet the various strict customized requirements of clients.

As a leading manufacturer of chains in China, to better support our customers and enhance our core competence, we have introduced continuous improvement concept in our company years ago, with regular CI events, we are not only maintain our original product advantages and excellent manufacturing technology, but also improve our lead time, quality, cost etc to customers.

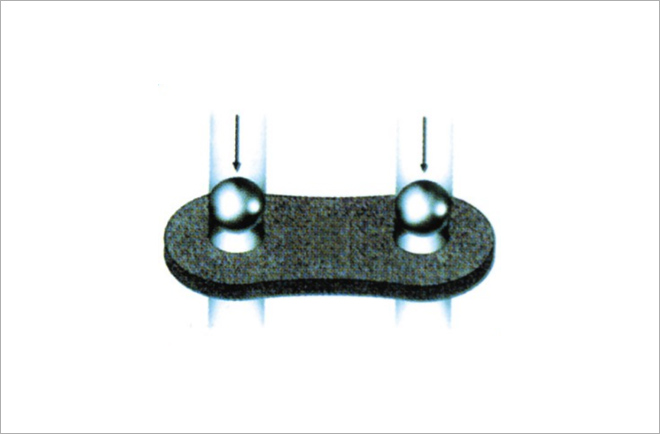

Unique Technology

Through years of industry knowledge accumulation and processing crafts optimization, six unique technologies have been formed, that improve and strengthen all aspects of the manufacturing process to enhance the accuracy, quality, and capacity of our chain products further.

- 01 Enhanced Extrusion of Chain Plate

- 02 Enhanced Shot Blasting of Parts

- 03 Automatic Image Detection

- 04 Auto Continuous Preloading

- 05 Auto Heat Treatment Production Multi-function Furnace

- 06 High-precision Laser Cutting Controlled by Program

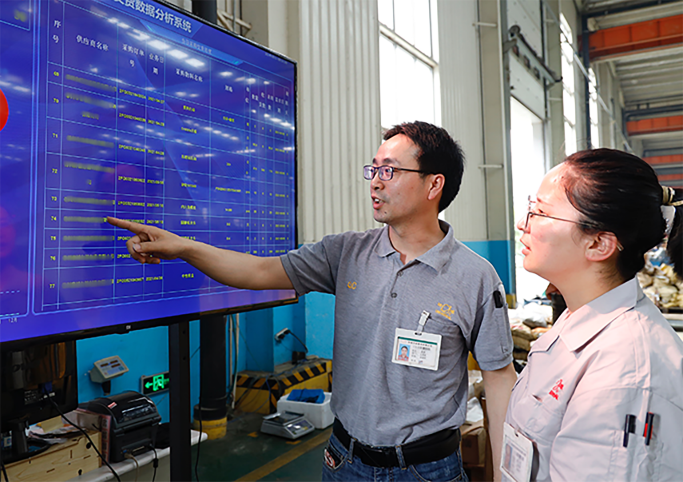

Intelligent Production Management System

Universal Chain deeply implements the concept of digital integration into all aspects of daily operations, which improves our response speed and execution efficiency, and also drives our partners to develop and progress together. This system lays a really solid foundation for meeting customer needs and rapid delivery.

Want to talk about your chain transmission products needs with us?

Please feel free to contact us whenever you have any question or demand in the chain transmission products. Our experienced expert team will respond to you in 24 hours.