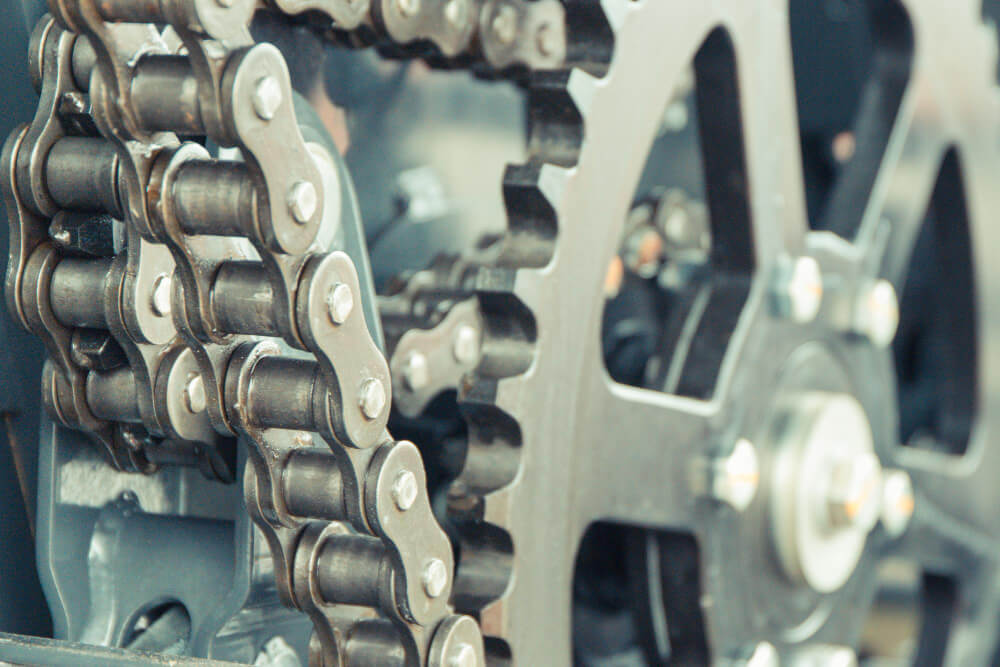

Roller chains are among the most widely used power transmission chains in industrial applications. Their versatility, efficiency, and robust design make them suitable for countless machines and mechanisms across diverse industries.

But did you know there are several distinct types of roller chains designed for specific purposes? The most common types of roller chains are standard, heavy-duty, double-pitch, and leaf roller chains

Understanding the different roller chain types is crucial for selecting the perfect one for your specific needs.

The Types of Roller Chains

Standard Roller Chains

Standard roller chains, also known as simplex chains, are the most common type. They offer a balanced combination of strength, size, and cost, making them suitable for various applications.

These chains consist of alternating inner and outer links connected by rollers that reduce friction during operation. Standard roller chains are available in various sizes, identified by a numbering system based on pitch (center-to-center distance between rollers). Popular choices include #40, #50, and #60 chains, with higher numbers indicating a larger chain size and higher load capacity.

Heavy-Duty Roller Chains

When standard roller chains meet their limits, heavy-duty roller chains step in.

Designed for use with significant loads and high tensile strengths, these chains boast thicker link plates and rollers than their standard counterparts. Their robust construction allows them to handle demanding environments, such as industrial machinery, agricultural equipment, and construction tools.

Double-Pitch Roller Chains

Double-pitch roller chains offer an interesting option for applications requiring high speeds but with lower loads.

These chains retain the same width as standard roller chains but with a doubled pitch. This results in a chain with fewer links per unit length, allowing for faster operation while maintaining sufficient strength for lighter loads.

Double-pitch roller chains are often found in applications like textile machinery, packaging equipment, and overhead conveyors.

Leaf Chains

Leaf chains or multi-strand chains, replace the typical outer link plates with leaf-shaped wires looped over the pins. This gives leaf chains incredible flexibility to run over smaller sprockets and negotiate tight turns.

Common applications include driving and lifting mechanisms on forklifts, cranes, and other material-handling equipment where tight articulation is paramount.

Specialized Roller Chain Types

The world of roller chains extends far beyond these core types. Here’s a glimpse into some specialized options:

- Self-Lubricating Roller Chains: These chains feature built-in reservoirs or special bushings containing oil or lubricant, minimizing the need for frequent external lubrication. This is particularly beneficial in applications where maintenance access is limited.

- Hollow Pin Roller Chains: These chains have a hollow pin in the inner link. This allows for attaching special links, plates, or other components, making them ideal for conveyor applications where components need to be attached to the chain for specific purposes.

- Plastic Roller Chains: A lightweight and corrosion-resistant option, plastic roller chains are ideal for low-load applications where hygiene or non-conductivity is a priority. They are commonly found in food processing lines, bottling plants, and conveyor systems handling lightweight materials.

For expert advice on selecting the ideal roller chain for your application, contact our team at Universal Chain today.