Standard vs. Quad-Riveted Pins: Making the Right Choice for Your Roller Chain

When selecting a roller chain, it’s the small details that determine long-term performance and safety. While factors like material and pitch are crucial, the method used to secure the pins—the very components holding the chain together—is a critical, often underestimated, engineering choice.

The riveting process directly impacts a chain’s connection strength, its resistance to fatigue, and its suitability for your specific application.

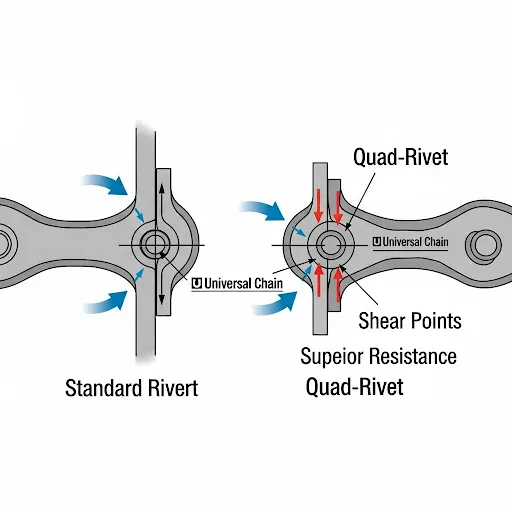

The two most common types are the standard (double) riveted pin and the quad-riveted pin. Understanding their differences is key to preventing premature chain failure.

The Workhorse: The Standard (Double) Riveted Pin

A standard riveted pin is secured by forming two rivet points on each end of the pin. This classic design has a long history of reliable performance in a wide range of applications.

- Key Advantages: Its simpler manufacturing process and lightweight design can help reduce the overall energy consumption of the drive system. It also offers a degree of flexibility during installation.

- Best Suited For: Standard riveted chains are the ideal choice for applications with moderate loads and smooth, steady operating conditions, such as in light-duty conveyors and general power transmission systems.

The Powerhouse: The Quad-Riveted Pin

For more demanding environments, the quad-riveted roller chain offers a significant upgrade in strength. This design features four symmetrical rivet points on each pin end, creating a highly stable “four-point” lock.

- Key Advantages: This structure dramatically increases the pin’s resistance to shear forces and torsional stress. It provides a much stronger connection that holds up against vibration and high-frequency impacts, preventing the side plates from working themselves loose.

- Best Suited For: It is the superior choice for applications involving heavy loads, high-frequency shock, or frequent start-stop cycles. Think of heavy machinery drive systems, agricultural equipment, mining conveyors, and other high-stress industrial environments.

Precision in Every Process: The Universal Chain Approach

At Universal Chain, we don’t believe in a “one-size-fits-all” solution. With our deep understanding of diverse operational demands, we have perfected both standard and quad-riveting processes with strict precision control.

Our goal is to ensure that whichever chain you choose, it is perfectly engineered to meet the intensity of its intended application. The choice isn’t about which riveting style is “better” overall, but which is correct for your parameters.

Are you weighing the needs of load capacity against energy consumption? Are you dealing with high shock loads that could compromise a standard chain?

Let our experts guide you. Based on your specific load, frequency, and operational data, we can provide professional advice to match you with the ideal pin configuration, guaranteeing the durability and safety of your equipment.

Ensure your chain is built for its purpose. Contact Universal Chain today for an expert consultation on your application.