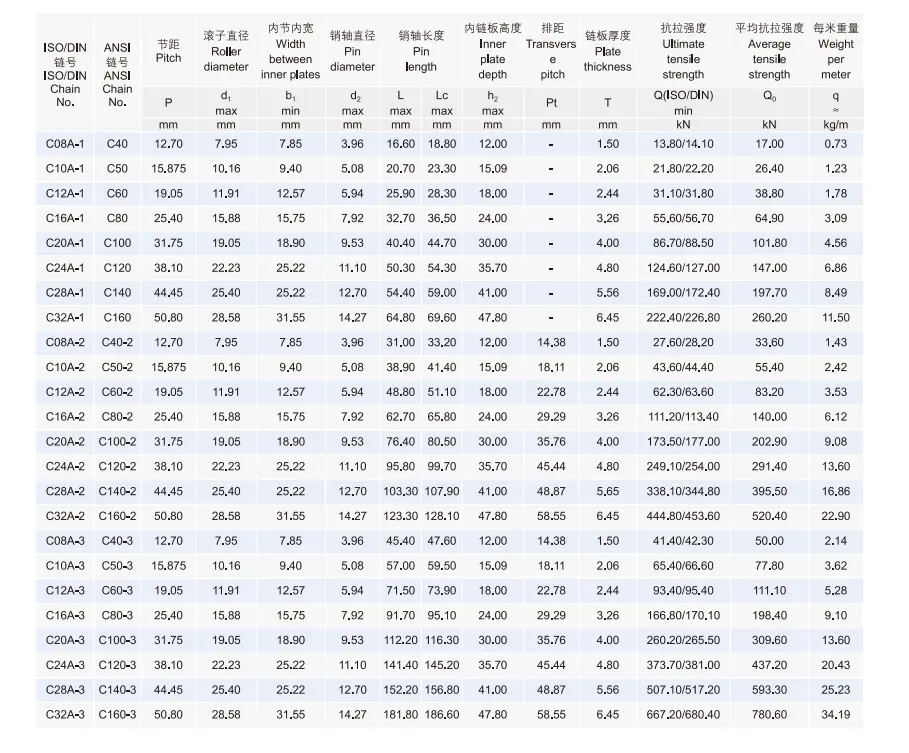

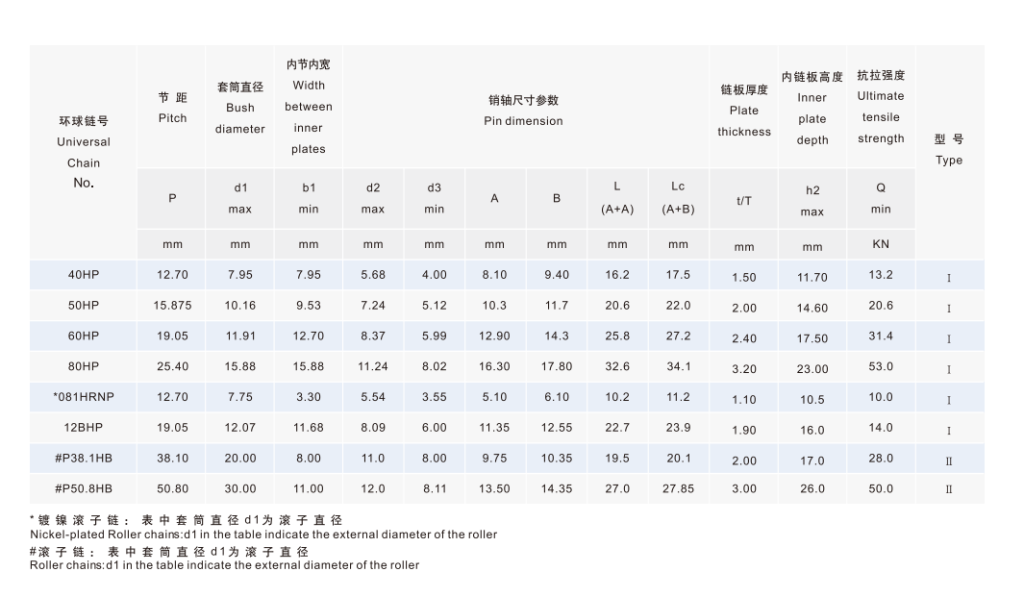

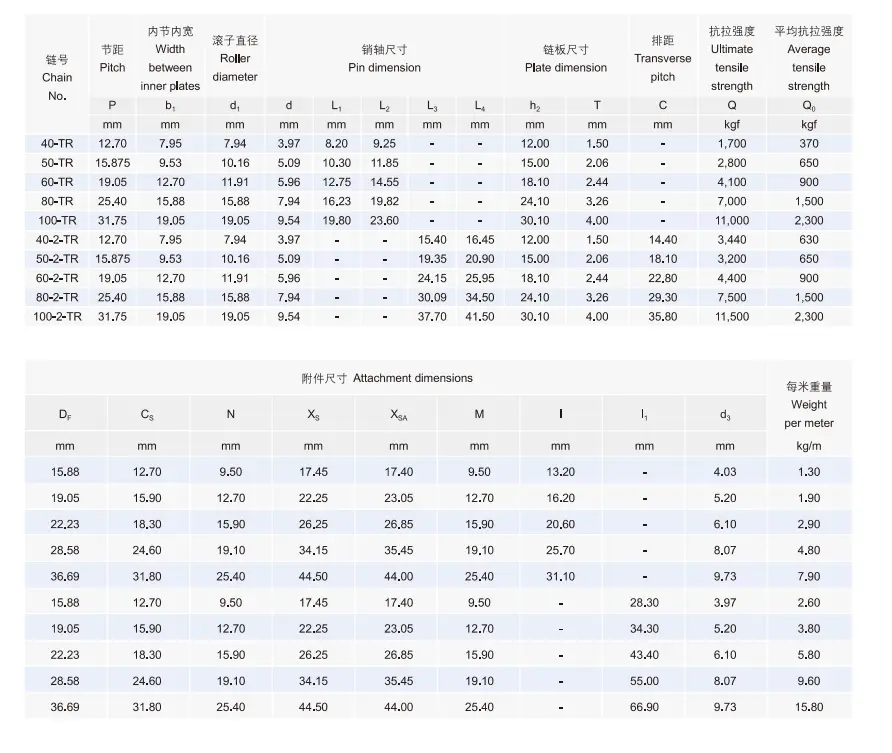

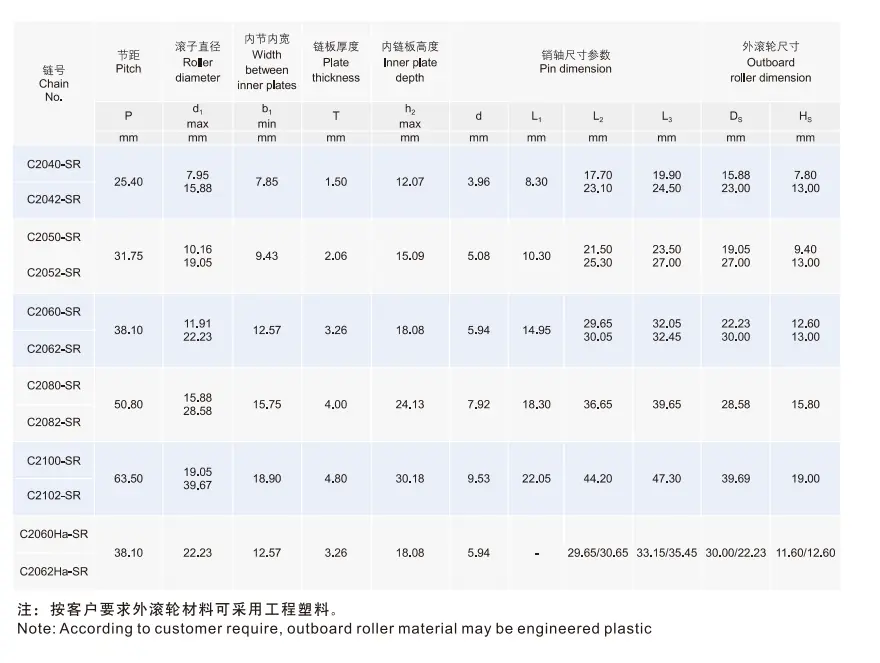

Conveyor Roller Chain size guide

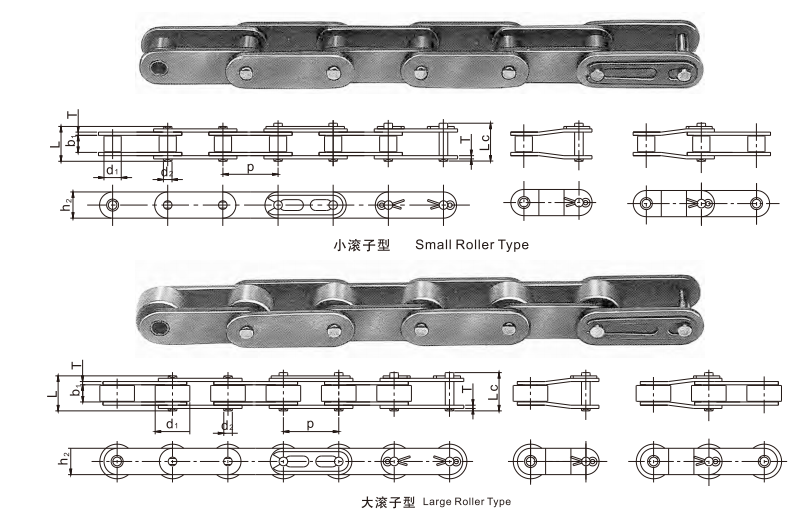

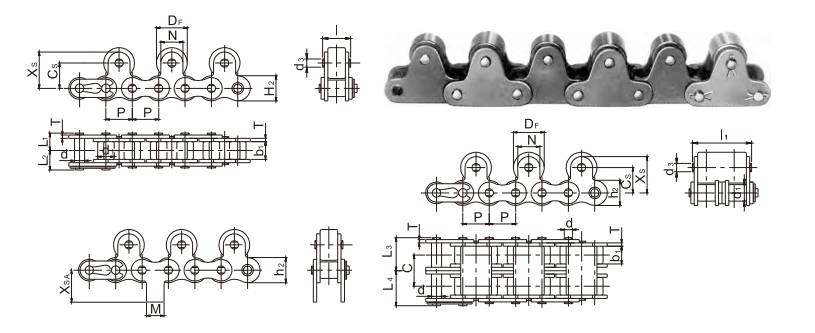

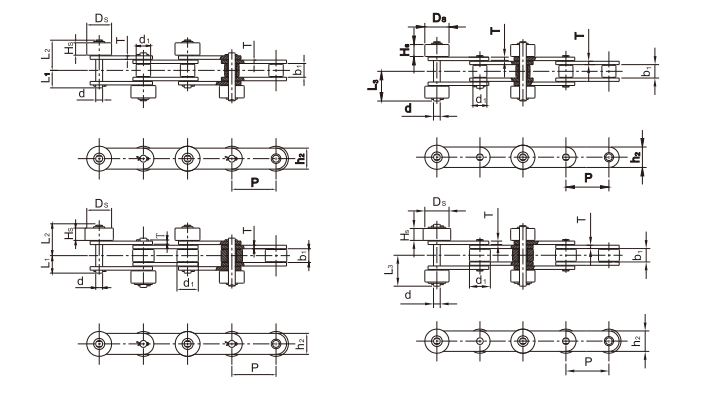

The conveyor roller chain is an essential component in material handling systems, designed for efficient transport of goods across various industries. Its robust construction ensures reliable performance under heavy loads, making it ideal for applications in the packagingand automotive industries. Key advantages include durability, precise positioning, and compatibility with diverse systems.

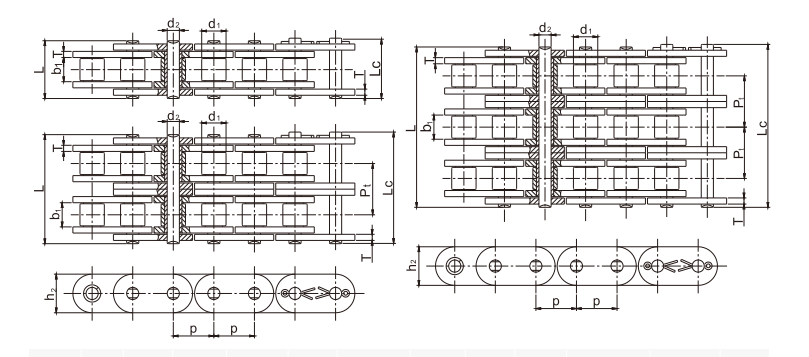

We stock a wide range of sizes and configurations, including ANSI, DIN, and ISO certified series chains, ensuring the perfect fit for any application. This extensive product range guarantees an optimum solution for your conveyor needs.

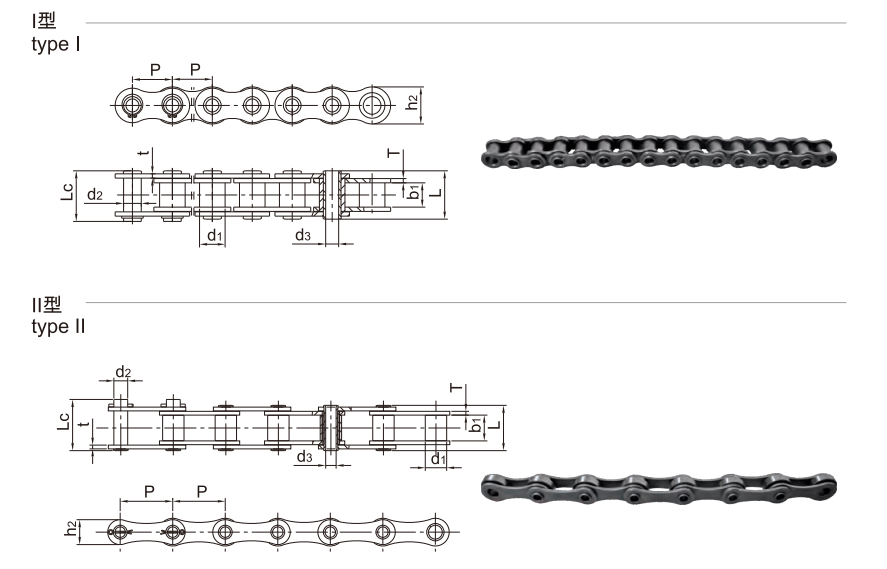

We also have a full line of stainless steel chains as well as hollow-pin chains. Explore our comprehensive selection to find the ideal chain for your specific requirements.