Definitive Guide on How to Measure Roller Chain Sizes

Before you can replace your roller chain, you must accurately measure its size first. Whether you’re working with roller chains for your machinery or just curious about the process, it is important to be guided.

So, how do you measure chain size? You need to identify the type of chain to be used, locate a straight section of the chain, and measure the pitch, roller width, and link plate thickness.

Let’s get into the details!

Why Roller Chain Measurements Matter

To review, roller chains are variants of your chain drives responsible for transmitting mechanical power on a wide range of machinery and vehicles. They look like chains of a bicycle, but more heavy-duty.

What that being said, roller chains are precision-engineered components. Each chain size, identified by a specific code, dictates crucial dimensions like pitch, roller width, and link plate thickness.

Using an incorrectly sized chain can lead to a cascade of problems such as premature wear, reduced efficiency, and chain breakage. Therefore, accurate chain size measurement is paramount to ensure smooth operation, extended chain life, and optimal power transmission.

Tools You Will Need

To measure chain size effectively, you’ll need a few basic tools:

- Calipers: This is the most accurate way to measure the key chain dimensions. A digital caliper with both metric and imperial units is ideal for versatility.

- Ruler or Tape Measure: While not as precise as calipers, a ruler or tape measure can be used as a backup if calipers are unavailable.

Optional, but helpful tools are:

- Chain Wear Gauge: This tool helps assess chain elongation, which indicates wear and tear. A worn chain may require replacement even if the base measurements seem correct.

- Master Link Removal Tool (if applicable): If your chain has a master link, you might need a specific tool to remove it temporarily for easier measurement.

Need help measuring roller chain sizes? Contact us today for expert assistance and find the perfect chain for your needs!

How to Measure Roller Chain Sizes

From determining the chain type to measuring the link plate thickness, these steps to measuring roller chain sizes must be carefully carried out.

First Step: Identify the Chain Type

First and foremost, familiarize yourself with the type of chain you’re measuring. Most roller chains will have a code stamped on the outer link plate that denotes the size. However, if the code is worn or missing, measurement becomes necessary.

Second Step: Locate a Straight Section of the Chain

Choose a section of the chain that is free of twists or bends for accurate measurements. This step ensures you’re measuring the actual length of the chain without encountering distortions from loops or kinks, which could lead to inaccurate measurements. In addition, a straight section paves the way for easier handling and modification, making it much simpler to take precise measurements using the matching tools.

Third Step: Measure the Pitch

Using your calipers, carefully measure the distance between the center of one roller pin to the center of the next roller pin in line. This distance is your pitch, which is crucial as it determines the chain’s compatibility with sprockets and other parts of your machine. Accurate pitch measurement is also vital since even the slightest variations can lead to improper fitting, wear, and chain system failure.

Last Step: Measure the Roller Width

Open the caliper jaws and measure the width of the roller itself, between the two side plates. Make sure to measure at the widest point of the roller. This step is important to guarantee the right alignment and fitting of your sprockets. Inaccuracies lead to increased friction, misalignment, and premature wear on both the chain and its associated components.

Optional Step: Measure the Link Plate Thickness

For some applications, knowing the link plate thickness might be important. Use the calipers to measure the thickness of a single link plate from one flat side to the other.

Common Roller Chain Measurement Mistakes to Avoid

Based on our experience handling replacement requests and incorrect chain returns, the following issues appear most often:

- Measuring on a bent or tensioned chain section

- Measuring pin-to-pin edge instead of center-to-center

- Ignoring chain wear and elongation

- Mixing metric and imperial readings

- Measuring only pitch and ignoring roller width

Even small errors can result in poor sprocket engagement or noise during operation.

Roller Chain Size Parameters Explained

The table below summarizes the core dimensions that define roller chain size.

| Parameter | What It Measures | Why It Matters |

|---|---|---|

| Pitch | Center distance between pins | Determines sprocket compatibility |

| Roller Width | Inner width between plates | Affects load distribution |

| Roller Diameter | Outside roller size | Influences contact with sprocket |

| Plate Thickness | Side plate thickness | Related to tensile strength |

These values together determine whether a chain can operate safely in your system.

Measuring New Chain vs. Worn Chain

| Condition | Measurement Accuracy | Recommendation |

|---|---|---|

| New chain | High | Use as reference |

| Light wear | Medium | Compare with standard chart |

| Heavy wear | Low | Replace before measuring |

A worn chain may show increased pitch due to elongation. This often leads to incorrect size identification.

Frequently Asked Questions

How Do I Identify the Roller Chain Size After Measuring?

To identify the chain size after measurement, compare your findings for your pitch, roller width, and the like to a roller chain size chart for accurate identification, such as what you can see from the previous section.

How Do I Measure the Pitch of a Roller Chain?

Measure your roller chain’s pitch by determining the distance from the center of a roller pin to the center of the next using calipers for precise measurements.

Can I Measure a Worn-Out Roller Chain?

Yes, definitely. But, you must keep an eye out for wear by comparing its measurements to those of new chains, manufacturer specifications, or roller chain size guides for accurate sizing. There are changes from when you measured your roller chain when it was still brand-new, for sure.

Applicable Standards for Roller Chain Sizes

For procurement and engineering validation, roller chains are commonly specified under:

- ANSI B29.1

- ISO 606

- DIN 8187 / DIN 8188

When sourcing chains internationally, always confirm which standard your equipment requires.

Find the Best Roller Chains From Universal Chain

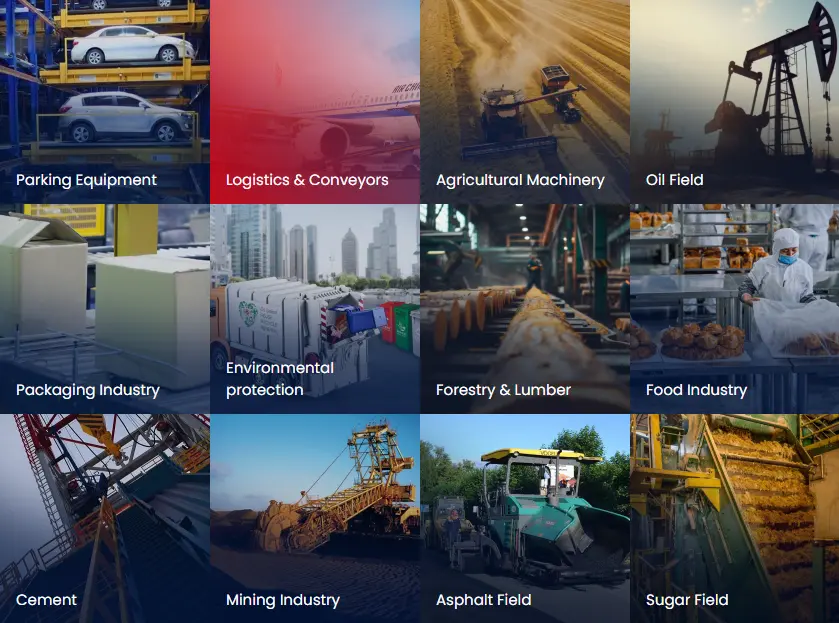

Established as early as the 1970s, Universal Chain manufactures and exports high-quality chains for various industries, such as:

- Aerospace

- Mechanical engineering

- Lifting equipment

- Parking and equipment

- Logistics and conveyors

- Agricultural machinery

- Oil

- Packaging

- Environmental protection

- Forestry and lumber

- Food

- Asphalt field

- Mining

- Sugar field

- Cement

The company’s culture is hinged on the spirit of craftsmanship, which champions endeavor, efficiency, and innovation that goes beyond expectations. Should you wish to accurately measure your chains with this brand, they have the official size charts on their website. No need to look elsewhere.

Do you have any questions about roller chains or need help finding the right one for you? Contact our team today!